Boasting exceptional durability, strength, and resistance to wear and temperature fluctuations, cast iron stands as a superior material choice for ball valves.

Control Your Flow with Cast Iron Ball Valves

Under the extreme conditions of industrial flow control situations, cast iron excels at maintaining the integrity and functionality of your valves, with exceptional strength and resistance to high temperatures and pressures.

With cast iron construction, ball valves provide reliable flow control, shut-off, and isolation capabilities in industrial applications from high-pressure water and wastewater treatment to gas distribution networks.

Together with premier ball valve manufacturers, American Stainless connects you to top-tier cast iron ball valves on nobody’s terms but yours to ensure your project’s success.

What are Cast Iron Ball Valves?

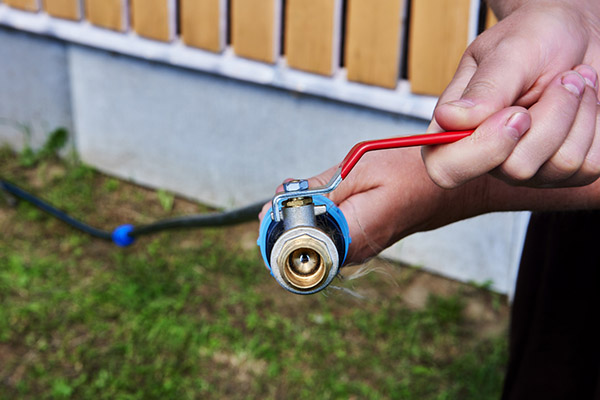

By using a fixed or floating ball to control the flow of fluid through pipe and tube systems, ball valves provide an extremely tight and reliable seal to prevent leaks and pressure drops. A cast-iron valve body provides exceptional strength and durability that make cast iron ball valves a long-lived and cost-effective choice for industrial flow control.

The Advantages of Cast Iron in Ball Valves

At American Stainless, we go beyond steel. Cast iron is the right material for ball valves in many industrial flow control situations due to the myriad benefits and advantages afforded by its exceptional strength and resilience, such as:

-

Durability and resistance to deformation under high temperatures and pressures

-

Resistance against wear, making it ideal for rigorous use in applications involving abrasive materials and high usage frequencies

-

A long service life and minimal maintenance requirements, contributing to low long-term operational costs

-

Robust performance characteristics that combine enduring performance with economic viability

Understanding the Most Common Types of Cast Iron Ball Valve

Not all high-pressure, high-temperature industrial applications are well-suited by the same ball valve type. Cast iron ball valves come in a wide range of shapes, sizes, and types to maximize effectiveness in various situations. Some of the most commonly used types include:

Floating

Ball Valves

In a floating ball valve, elastomeric seats hold the ball in place to maintain a tight seal. Floating cast iron ball valves are especially useful and reliable in moderate pressure applications, and their simplicity makes them easy to maintain.

Trunnion Mounted

Ball Valves

Unlike floating balls valves, a cast iron valve with a trunnion mounted ball anchors the ball at the top and bottom. While the design is more complex, it is also sturdier and more well-suited for high-pressure and high-volume applications.

Top Entry

Ball Valves

Valve maintenance can be challenging if the valve’s location makes it difficult to be removed. In top entry ball valves, the ball and internal parts are inserted from the top and can easily be removed and inspected without removing the body from the pipeline.

Full Port/Full

Bore Ball Valves

Full port cast iron ball valves have an internal diameter equal to the diameter of your pipeline, maximizing flow capacity, minimizing pressure drop, and allowing easy passage for pigging devices during cleaning and maintenance.

Choosing the Right Cast Iron Ball Valve

To get optimal performance, durability, and cost-efficiency out of your ball valve, it’s not enough to select the right material—you also need to make sure you’ve chosen the right valve design for the fluid it will be handling, its intended flow rate, and the valve’s environment. To ensure you choose the right valve type, take into account your project’s demands and constraints and consider:

Fluid

Characteristics

Differing cast iron valve designs offer vary degrees of resistance to fluid temperature and pressure. Choosing the right valve for your fluid’s characteristics also ensures maximum longevity and reliability for applications involving abrasive or corrosive fluids.

Flow Control

Requirements

Understanding the difference in flow rate between full port and standard port ball valves ensures that your system has the appropriate flow rate capacity and level of precision in its flow control capabilities to suit your project’s demands.

Accessibility

The functionality of your cast iron ball valves should be weighed carefully against how easy it will be to access your valve’s internal components to ensure you can perform maintenance, cleaning, and repairs without significantly impacting your operations.

Cast the Right Player in Your Flow Control System’s Performance

Start a Quote

Exploring Cast Iron Ball Valves in Industrial/Commercial Flow Control

Cast iron provides ball valves with durability, high resistance to wear, and capability to handle extreme temperatures and pressures that make them ideal for industrial applications such as:

Cooling Water Systems

Cast iron ball valves are used in the cooling systems of steel mills to regulate the flow of water used to cool down equipment and steel products.

Chemical Processing Lines

In the pulp and paper industry, cast iron ball valves provide exceptional flow control for the chemicals used in pulping and paper-making.

Steam Distribution

For pipe fabricators working on steam distribution systems, cast iron ball valves provide effective steam flow management throughout the system.

Pharmaceutical Waste Management

Using cast iron in the bodies of ball valves offers efficient flow control in systems designed to safely dispose of chemical and biological waste.

Cleaning In Place Systems

Ball valves made of cast iron provide reliable distribution of cleaning agents used to sanitize food and beverage processing equipment.

Commercial HVAC Systems

Cast iron makes ball valves especially suitable for regulating the flow of hot and cold water for heating and cooling purposes.

Cast Iron Best Practices: Installation, Operation, and Maintenance Tips

Cast iron ball valves are well known for their exceptional durability and long service life due to their strength and resistance to wear. However, ensuring a long service life and minimal operating costs for your ball valves means taking good care of your valves through their entire lifespan.

Installing Your Cast Iron Ball Valves

- Before installation, inspect the valve for any damage or debris and ensure its compatibility with your pipe infrastructure and the fluid it will control.

- Make sure to properly align the valve with the pipe to prevent stress or uneven pressure.

- Choose gaskets and seals that are compatible with the type of fluid and the temperatures your valve will be expected to handle.

- Prevent cracks or warps in your valve body by avoiding over-tightening nuts and bolts when connecting the valve.

Operating Your Cast Iron Ball Valves

- Always operate your valve within the pressure, temperature, and flow rate limits specified by its manufacturer.

- Gradually open and close valves to prevent water hammer and safeguard your valve and pipe systems against damage.

- Periodically cycle the valve between open and closed positions to prevent sticking, especially in systems that are not used frequently.

Maintenance and Troubleshooting

- Conduct regular inspections for signs of wear, leakage, or corrosion so you can catch small and easily fixable issues before they threaten your operations.

- If your cast iron ball valves are used with sediment-laden abrasive fluids, periodically clean their internal components to prevent clogging and ensure proper sealing.

- Replace worn seals, gaskets, and other wearable parts to maintain a tight seal.

- If needed, periodically apply and re-apply protective coatings or paints to prevent rust in especially corrosive environments.

Get the Cast Iron Ball Valves You Need On Your Schedule with American Stainless

When your project calls for the unique advantages of cast iron, only the best will do. Through our numerous partnerships with best-in-class for ball valve manufacturers, extensive experience in the US Southeast’s leading industries, and unmatched quality system, we deliver ball valves made from high-quality cast iron on-time so your projects won’t go over-deadline or over-budget.

Get started on a quote today and discover the American Stainless difference.